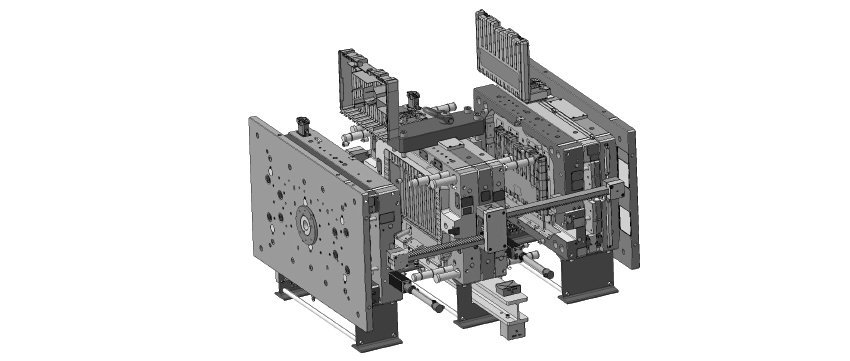

Moulds with multiple opposing surfaces, which enables a reduction of the projected area, avoiding the need to use bigger injection machines. The results are the duplication of the cavities numbers and consequently the increase of the injected parts and productivity.

— TECHNOLOGIES —

Injection process consisting of adding gas to plastic during the injection phase. This process is of bigger advantage in thicker parts in terms of costs, due to the material saving and also offers benefits in terms of engineering due to the weight reduction.

Plastic injection in alternative cycles. This process offers advantages in terms of optimisation of the parts quality, due to longer cooling times.

With this technology it is possible to remove the excess material and create empty zones inside the part. This way geometrical defects are avoided on the part and there is an increase of the part packing.

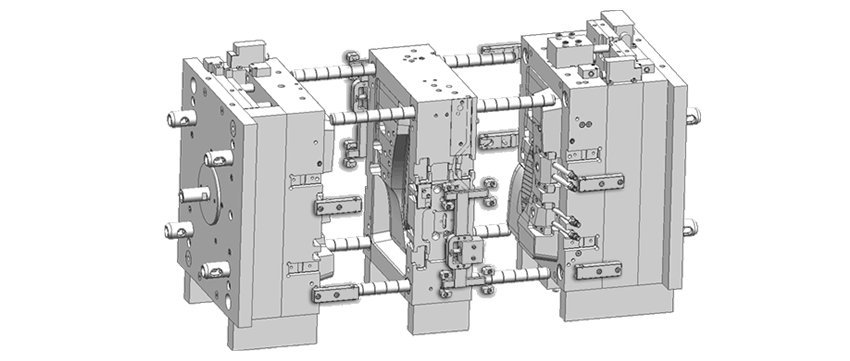

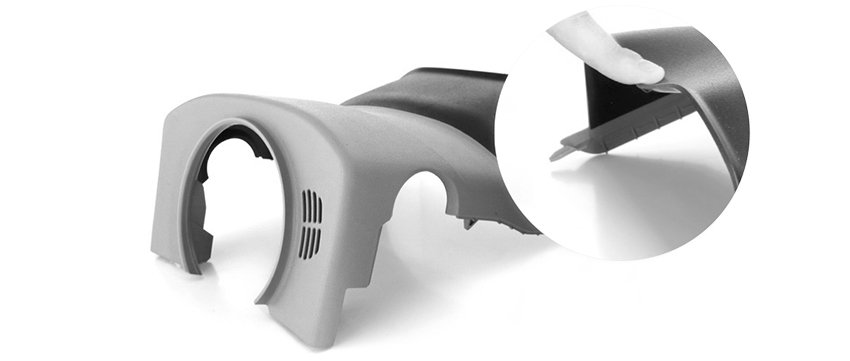

With this technology it is possible to combine two or more materials in the same part. Depending on the need and/or requirement, the customer can choose from a transfer, rotary table, core back or combined mould.

This technology allows the integration of inserts before the molding stage, so that the connection with the moulded plastic part becomes permanent.

With this innovative technology it is possible to quickly heat the mould, during the same cycle and during the filling stage and cool the mould after this process is finished. The main advantages are the elimination of welding lines and parts with higher visual quality.

— SERVICES —

R&D

In a world where technology is in constant evolution, DRT, through its own R&D Department, aims to remain at the forefront of this sector. This department has been developing many projects in the field of integration of pioneering technologies, in order to optimise the entire tooling development and conception process.

Read More

Read Less

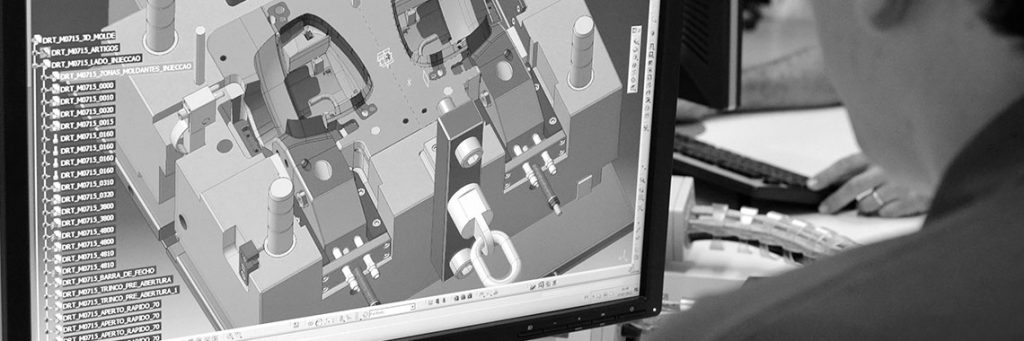

ENGINEERING

Our Engineering Department counts on the support of a professional team with an extensive knowledge on the industrial and plastics processes. By using CAD softwares (Catia V5-6 R2014, CREO 2.0, SIEMENS NX10) and CAM/CAE (Hypermill, Powershape, Lenoin, Moldex 3D), our team assures in a specialised and professional way the development and follow up of all stages of the project conception.

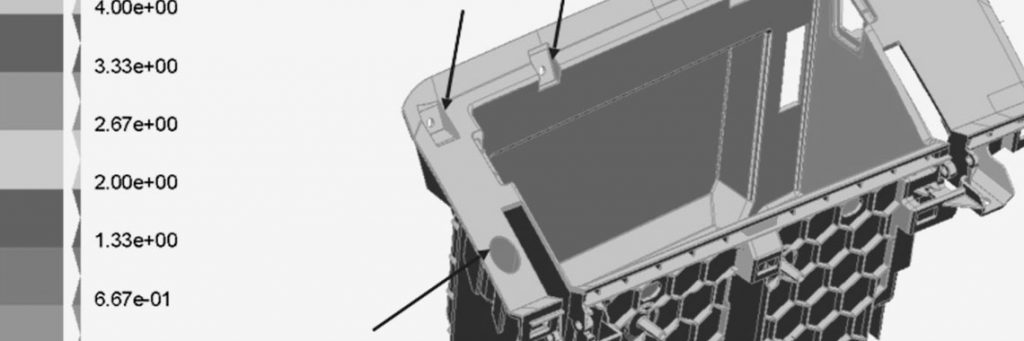

CAE ANALYSES

By means of Computer Assisted Engineering (CAE) it is possible to simulate the injection process still in the initial stage of the project by making rheological and structural analyses.

The rheological analyses enable us to optimise the location and sequence of the injection points, to improve the cooling process and to foresee the possibility of warpage and shrinkage.

Read More With this service, DRT assures the involvement and cooperation with the customer since the part development stage, making it possible to understand, still on a project stage, which optimisations must be implemented in order to avoid possible errors. All this will result in time and costs saving. Read Less

FEASIBILITY STUDIES

This initial analysis made to the plastic part and to the mould concept will make it possible to identify critical areas and present solutions on how to improve the final article, in order to implement them on the mould. This way we assure the mould lifetime for serial production, also aiming to reduce time and costs.

PROTOTYPING

Rapid Prototyping plays a basic role in the initial phase of each project. This area was created to complete the range of services to our customers.

The possibility to check the functionality of each part, the guarantee of the fastest time-to-market and the costs reduction of the project are of such significance, that today all the projects with ambition contract Rapid Prototyping and Rapid Tooling.

DMLS · Laser Sintering

This technology consists of building layer by layer, making it possible to have a simultaneous production of several parts. One of the biggest advantages is the possibility of making cooling channels very close to the moulding area in parts with a difficult geometry. This method not only offers an optimised cooling of the part, but it also reduces the cycle time in an effective way and enhances the product quality.

Tryouts

DRT has an injection area for mould trials with capacity between 210 Tons and 1200 Tons, where it is possible to make try-outs and pre-series in different types of moulds: serial tools, GID, multi-component and vario-cooling.

Turnkey

At DRT Group you can find all specialisations, from the design to the manufacturing of sets of complex moulds, monitored by specialists in various areas from the start of the project.